- Consultancy

Finite Element Analysis

Finite Element Analysis

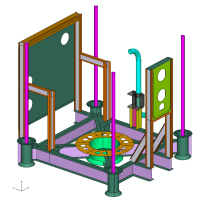

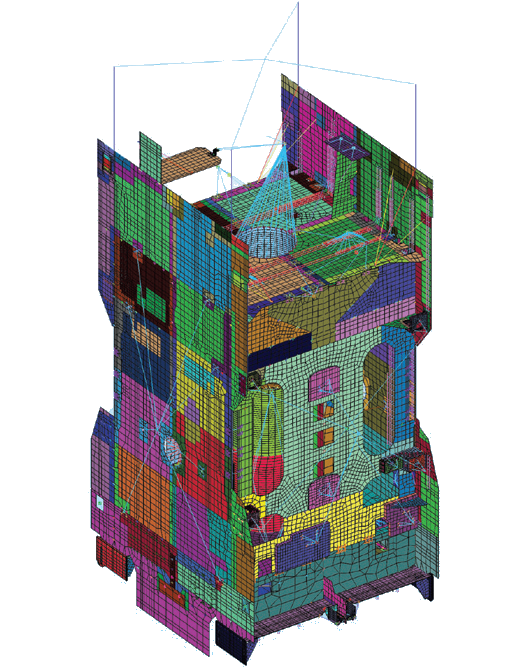

Zentech provides engineering consultancy services for the application of the finite element method to a range of industrial problems. These include non-linear static analysis (e.g. plasticity, contact, large displacements) and dynamic analysis (e.g. modal analysis, impact/crash, transient analysis).

We offer expert services in carrying out detailed component analysis. Our services have proved to be invaluable to many industries with very significant implications in both improving performance of original designs and reducing manufacturing and material costs.

We have developed advanced and complex non-linear finite element tools and models to predict the onset and growth of existing flaws in material. We also have the capability to predict the residual life of damaged equipment.

Our consultancy services on a range of commercially important applications include:

- leak before break studies of welded connections

- forensic analysis to examine the effect of roll and mis-alignment of the roller bearing on fatigue crack growth development

- damage tolerance assessment in aircraft engine components

- modelling defects starting from sub-surface inclusions in a spherical roller thrust bearing assembly

- linear and non-linear analyses to determine allowable residual strength criteria for vehicles with in-service flaws

- creep and fatigue crack growth modelling in high temperature nuclear power plant components

- fatigue analysis of riser hang-off structure for an offshore field development

- analysis of drop-load on a subsea structure

- laying of pipelines and riser systems.