- Software

- Zencrack

- What’s New in Zencrack?

Zencrack 9.0-1

What's New in Zencrack?

Zencrack 9.0-1

Zencrack version 9.0-1 was finalised on 25 January 2022

This version contains a completely new remeshing capability to speed up the creation of meshes containing cracks:

- mesh-independent geometry definition of initial crack with remeshing for the initial crack and subsequent crack growth

- remeshing capability in the Abaqus interface

- all crack-block meshing capabilities from previous Zencrack versions remain available

- available for Windows 10 (Windows 7 and Windows 8 also supported)

Remeshing Capability

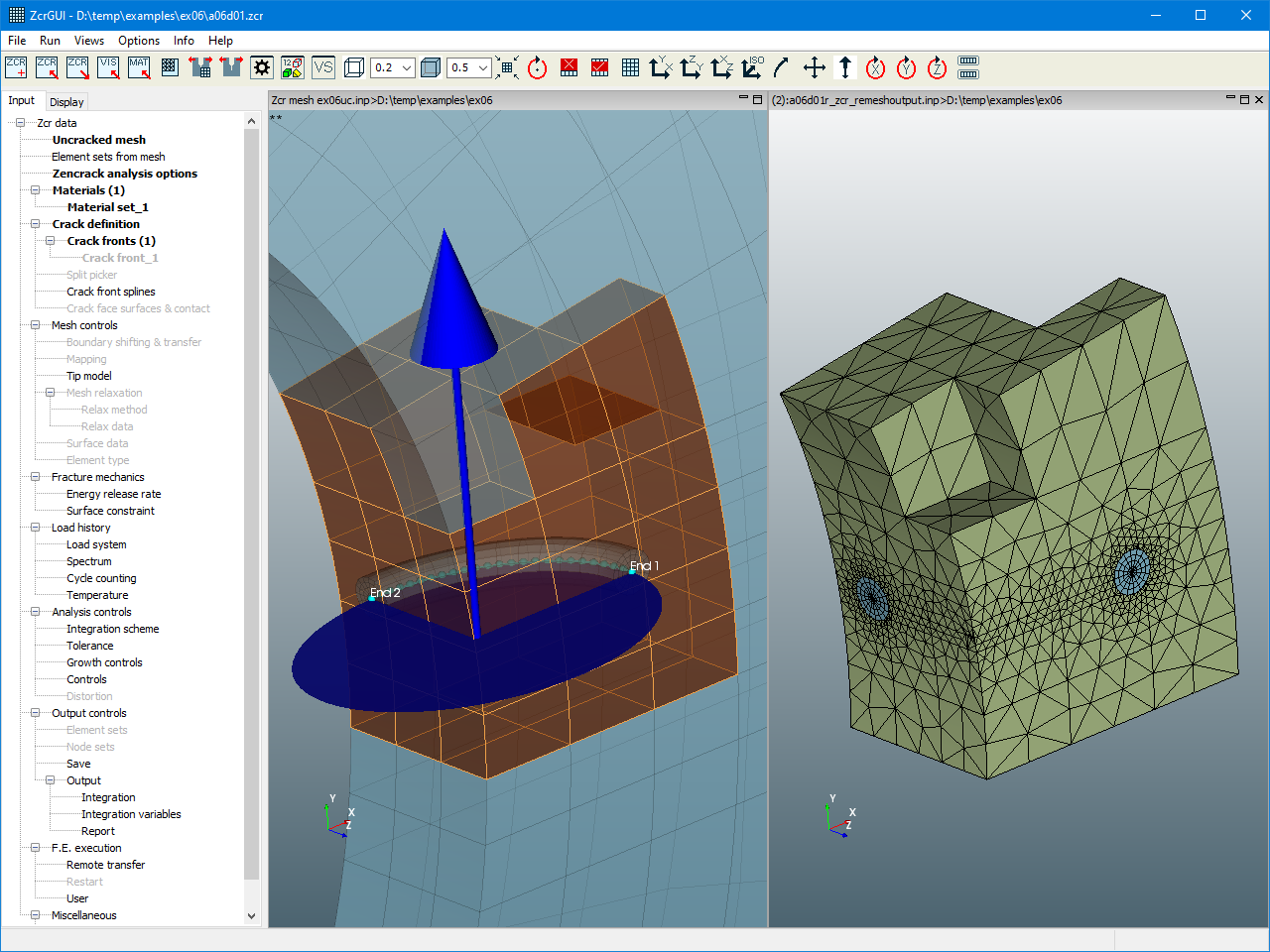

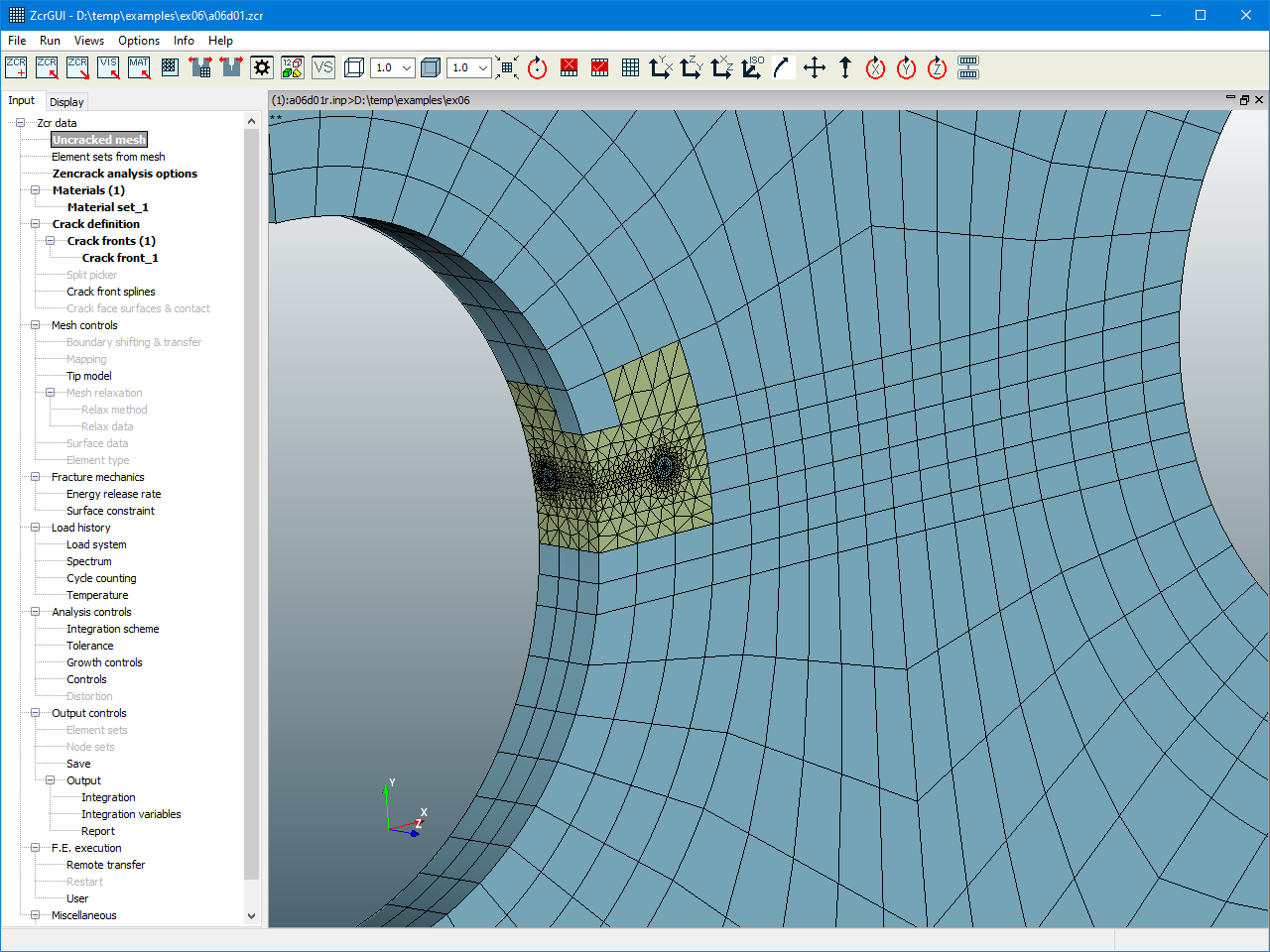

A new remeshing capability provides mesh independent crack insertion into an uncracked mesh. This approach simplifies the creation of 3D models containing cracks by using a purely geometric definition of an initial crack.

An existing uncracked mesh can be used "as-is" with, in most cases, no need to perform special partitioning or meshing of the uncracked geometry. This means that, for example, a single uncracked mesh can be used to develop models of significantly different cracks by simply changing the geometric crack definition.

- initial crack and crack growth

- remeshing for analysis of initial crack only

- remeshing for general non-planar 3D crack growth using the existing load system methodologies in Zencrack for fatigue, time dependent and combined fatigue/time crack growth prediction

- geometric definition of an initial crack

- initial crack location is fully independent of the underlying mesh

- the underlying mesh may contain hex or tet elements

- crack at a symmetry plane, surface breaking or fully embedded

- initial crack shape may be straight or elliptic (either full ellipse or elliptic arc)

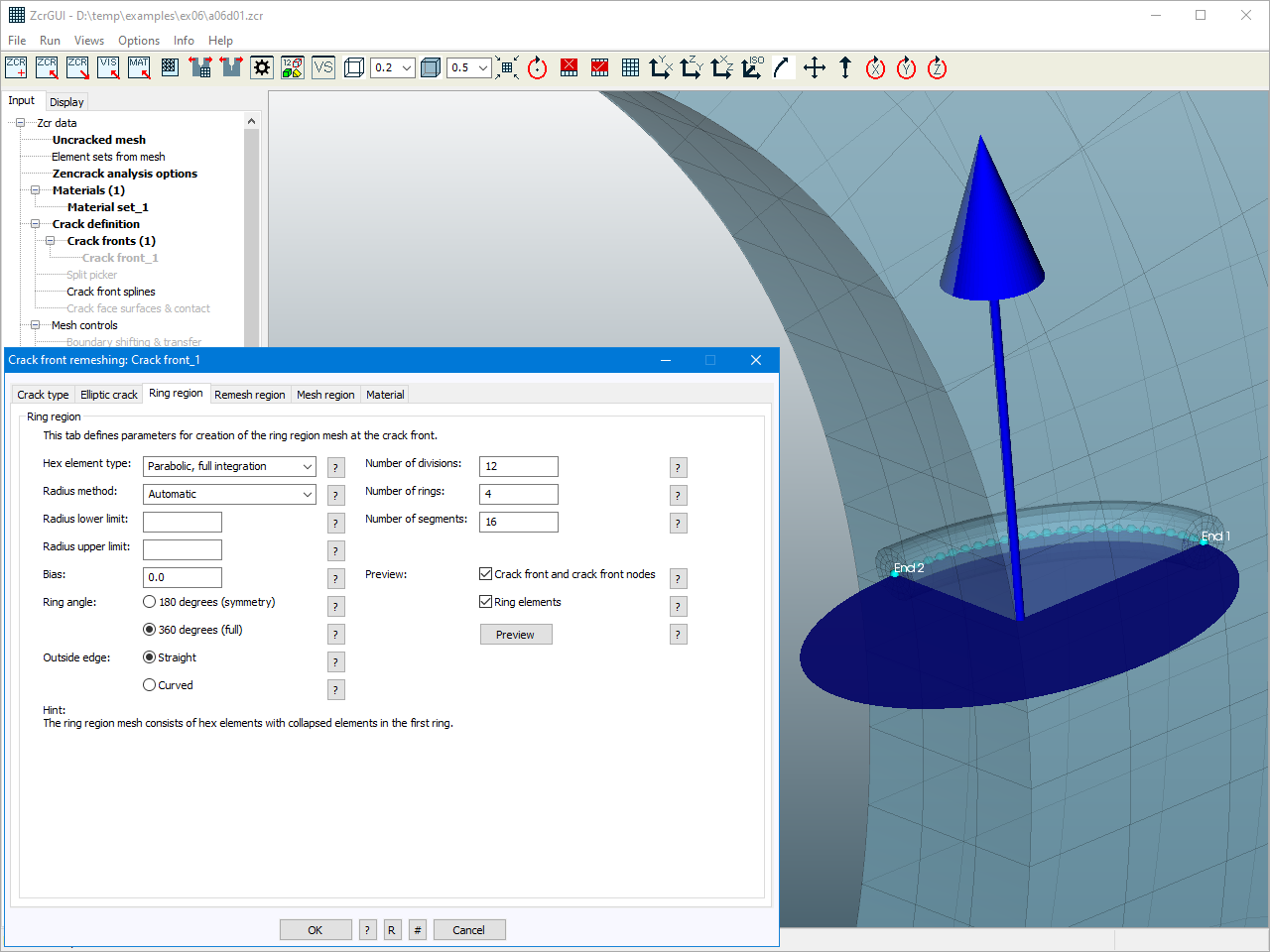

- remeshed region split into hex rings and surrounding tets

- rings of hex elements at the crack front with ring mesh density controlled by the user

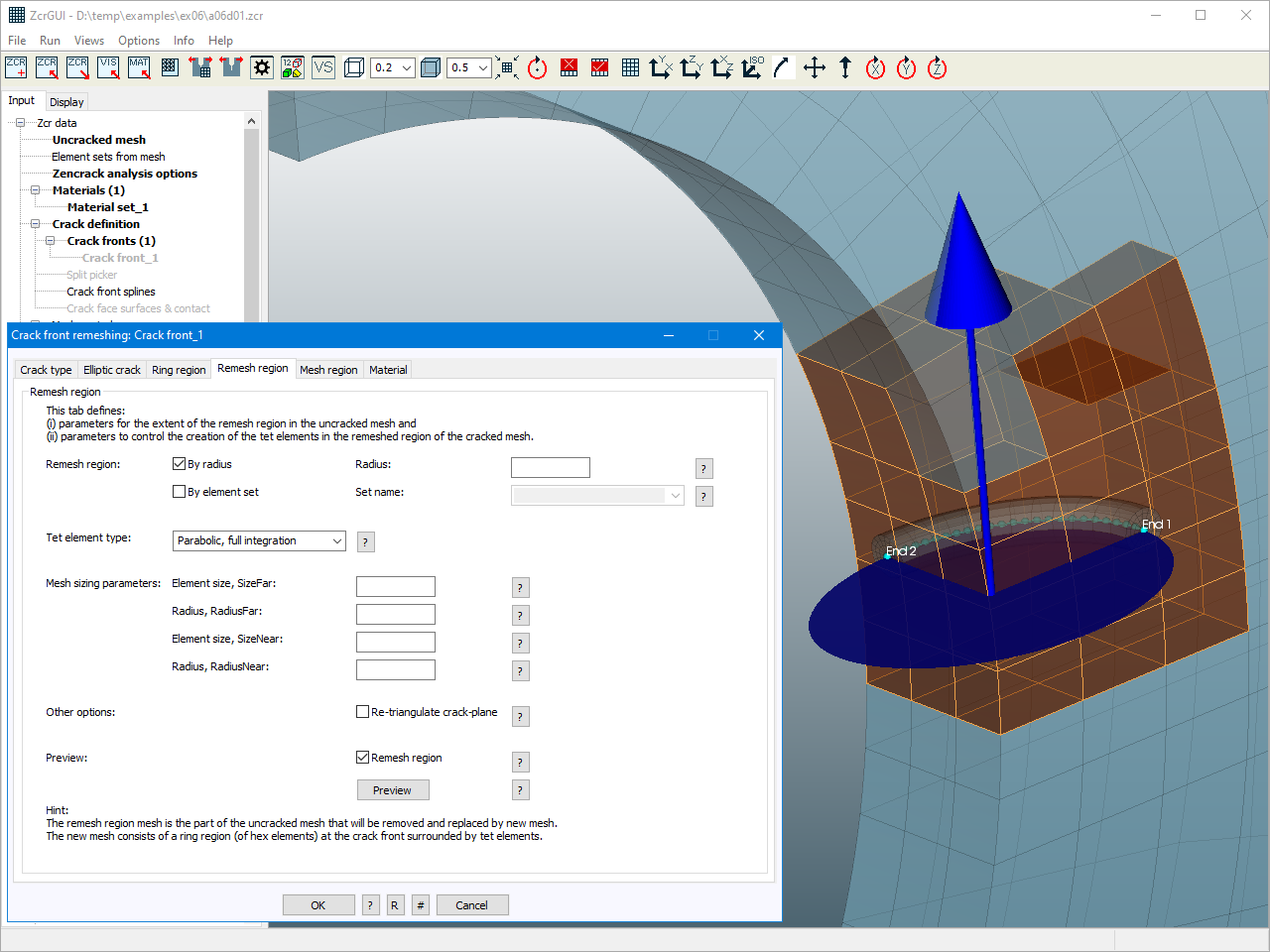

- tet mesh surrounding the rings

- fully automatic calculation of the extent of the remeshed tet region and mesh density within that region (with manual control if desired)

- support for static, thermal and coupled analyses

- update of displacement boundary conditions, pressure loads, surface definitions, film coefficients and temperatures in the remesh region

- optional application of pressure and/or film coefficients to the crack face

The remeshing capability is fully supported in the Zencrack GUI with options to preview various aspects of the initial crack definition, including:

- option to define geometric positional data by picking nodes in the uncracked mesh

- preview of the geometric crack definition

- preview of the hex rings at the crack front

- preview of the remesh region

- preview of the remesh region with the crack inserted

Other developments in Zencrack

- Implementation of crack growth direction from stress intensity factors based on the work of Richard et al.

- Ref: H.A.Richard, M.Fulland, M.Sander, Theoretical crack path prediction, Fatigue Fract Engng Mater Struct 28, 3-12, 2005.

- Extension of the processing available for interaction integrals to allow them to be used to drive a crack growth analysis.

- Support for the Ansys option for specifying the auxiliary field solution when calculating interaction integrals: mixed, plane stress or plane strain.

- Re-working of some of the options on the *ENERGY RELEASE RATE keyword to accommodate some of the above changes and to allow future additions.

Changes in the Zencrack GUI

- New input, preview and display options to support the new remeshing capability for crack insertion into an uncracked mesh (see additional examples below).

- Re-working of the Energy Release Rate screen to accommodate the changes described above.

- Improved performance for large meshes (faster import and manipulation).

- Import and optional display of the material regions defined in a mesh.

- Identification of disconnected mesh regions.

- Labelling of profiles when displaying crack growth profile results.

- Labelling of splines (Input Tab crack front splines and Display Tab splines).

- Ability to add multiple meshes into one viewport.

- Ability to display some types of surface definitions (initially to support remeshing previews).

Examples of remeshing - crack growth

This section presents four examples of crack growth prediction, each carried out in a single automated analysis.

Inclined straight starter crack in a 4-point bend specimen with a hole

An initially inclined crack which straightens and grows past the hole. The final animation shows a straight through (not inclined) starter crack located closer to the hole. This deviates towards the hole rather than growing past it.